EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

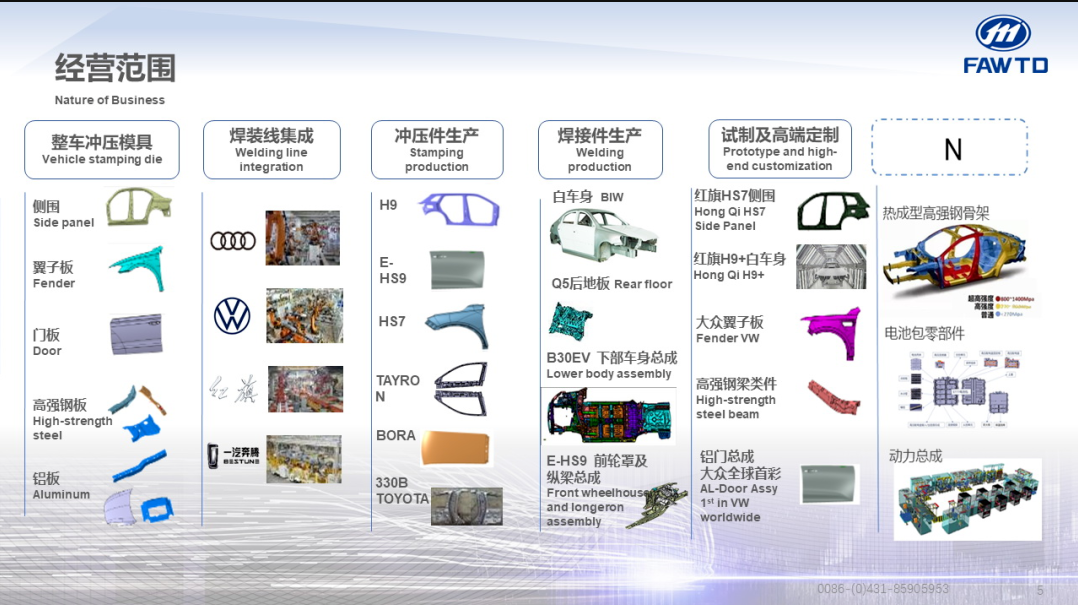

To realize the vision of becoming the "strongest in China and world-class" automotive tooling digital intelligent manufacturing enterprise, FAW Moulding has adhered to strategies of "technological informatization," "management digitalization," "equipment modernization," and "international business," for many years. As FAW Moulding's brand effect, product quality, and manufacturing process levels enhance continuously, each "action" in building its smart factory is viewed as a directional marker for the industry, becoming an imitation target for enterprises aspiring toward advanced manufacturing. Being among the first to engage with FAW Moulding in digital projects, EMAN has repeatedly driven the implementation of FAW Moulding's smart factory.

From vehicle design to tooling manufacturing, a unified principle must be followed, demanding a high level of integration. Such development facilitates comprehensive control over body quality, costs, and timelines. Before the 21st century, Chinese mould and fixture departments or companies often worked in silos, finding communication difficult, delaying many issues until the production preparation stage, severely restricting the product quality of white bodies and production cycles.

Originating from FAW Tools Factory’s die and jig workshops, FAW Moulding restructured on July 9, 1999, into FAW Mould Manufacturing Co., Ltd. After restructuring, FAW established a sedan full-vehicle mould manufacturing technology platform, becoming the first domestic company to achieve integrated mould and fixture manufacturing.

To consolidate technological and managerial competitive advantages, FAW Moulding needs a solid “backbone” in the form of an advanced, intelligent digital factory. At the heart of this is the continuous enhancement of digital R&D, manufacturing, and management levels. With the accumulation of vast manufacturing technical data by the early 21st century, FAW had the foundation to build a digital factory while the industry was embracing mould and fixture integration.

At that time, FAW Moulding’s workshops simultaneously handled 200,000 to 300,000 workpiece procedures, making reasonable manual production planning impossible. Moreover, FAW Moulding was challenged by product changes, quality incidents, and inter-departmental processing commissions, significantly complicating management.

In 2005, EMAN was a pioneering company developing industry-specific mould management software in China. With a strong professional backdrop from the State Key Laboratory of Material Forming and Die & Mould Technology at Huazhong University of Science and Technology, and a passion for domestic software innovation, FAW Moulding partnered with EMAN to achieve lean management. By analyzing the characteristics of white body tooling products and work processes, both parties developed and implemented a system for key segments in mould production, constructing an information management system tailored to FAW Moulding’s production characteristics, achieving successful results in practice.

With EMAN’s Mould MES System, FAW Moulding achieved intelligent management from master project plans, departmental monthly plans, workshop work plans (detailed to each team and machine), to acceptance plans (internal and external). Managers at all levels associated with production could track differences between actual and planned executions through the Mould MES System, identifying and resolving exceptions early. Besides calculating processing and setup work hours, the system allows comprehensive analysis of quality issues registered during manufacturing, facilitating overall product information statistics.

The successful implementation of the Mould MES System enabled FAW Moulding to benefit from digital transformation: mould quality increased by 15%, process preparation efficiency improved by 50%, production schedule completion rate reached 90%, delayed moulds decreased by 25%, and equipment utilization rose from 60% to 80%, representing a qualitative leap forward for FAW Moulding and laying an important foundation for ongoing collaborative stability.

Rising labor costs are a persistent challenge in manufacturing. As an industry leader, although FAW Moulding can mitigate some cost increases through its strength, the insufficient in-house support for small part processing raised concerns at FAW Moulding’s executive level. Given the company’s overall capacity demands, mould products have 40% small parts requirement, while welding products need 80%. These parts demand long processing hours with high component hardness, often leading to issues like tool breakage and severe tool wear during processing. When such incidents occur, they necessitate stopping the current process, replacing the tool, restarting the program from the beginning, wasting machine time, and reducing processing efficiency.

Tips: FAW Moulding’s small parts refer to miniature components for automotive panel stamping dies, such as inserts, sliders, and wedges.To reduce reliance on human labor and maintain firm control over production capacity and quality, enhancing automation capabilities is crucial. Hence, FAW Moulding chose small parts as a pilot and, in collaboration with EMAN, began to plan for an intelligent manufacturing workshop for small parts processing.

In 2022, after six months of assembly line setup, a fully automated flexible intelligent manufacturing workshop, consisting of 9 processing devices, a pre-adjustment unit, and over 30 meters of track, saw the successful operation of its first-stage project, officially marking the establishment of the first domestic small parts flexible intelligent manufacturing benchmark workshop. The workshop aims at staff reduction and production increase through multi-process multi-machine flexible automation, on-line APS scheduling, AGV logistics, and on-machine inspection, addressing manufacturing issues like difficult plan control, excessive human dependency, high equipment idleness, and low production efficiency for FAW Moulding.

Highlight 1: Online APS Scheduling

FAW Moulding's small parts flexible manufacturing landmark workshop automatically runs processes guided by the Mould MES system’s instructions on process, task, and working hours. The automation system undertakes tasks like material plan statistics, programming task allocation, pre-adjustment task planning, tool preparation, machine status, processing scheduling, and material handling, achieving multi-process scheduling across 9 machines within the line. After automated processing makes way, the machine automatically reports back to the Mould MES System, which calculates part processing time, equipment hours based on feedback.

Highlight 2: Continuous Processing with Tool Change Capability

During tool breakage or change-offs, manual intervention allows marking of completed processes; the machine continues processing the broken tool procedure, significantly saving time and enhancing machine processing efficiency due to the line’s flexible design.

Highlight 3: Task-Driven AGV

With production task status and delivery demands driving AGV flexible dispatch, it breaks traditional point-to-point fixed-call delivery, avoiding surplus, delays, or mismatched deliveries. AGV logistics vehicles carry workpieces to be processed, completed workpieces, and irregular workpieces between the pre-adjustment unit and assembly line. Meanwhile, sensors precisely monitor material locations, ensuring stable AGV logistics vehicle operation.

Highlight 4: 3D Lightweight Inspection Report

In the process inspection phase, the automated flexible production line efficiently positions workpieces through a work order clamping function without manual intervention, reducing manual error probability. Following processing, on-machine inspection automatically initiates, creating an easily viewable 3D lightweight inspection report supported for modifications.

Highlight 5: Workshop Data Collection

The complete workshop uses a digital data collection system to gather and analyze production data, displaying it in real-time on workshop dashboards, not only illustrating current tasks, part deadlines, processing progress, equipment status, assembly line load, and personnel work hours but dynamically showcasing subsequent task information and production progress transparently. Furthermore, the 9 machines have internal video monitoring for real-time anomaly supervision, automated loading and unloading of machines, AGV operation observation, with recording playback supported, ensuring a transparent traceable production process.

With the implementation of the small parts flexible manufacturing benchmark workshop’s first-stage project, FAW’s machine equipment utilization increased from under 60% to over 90%, part processing efficiency rose by over 20%, virtually eliminating outsourced part processing, reducing workshop staffing from 9 to 3, and maximizing small parts processing profitability, establishing a robust foundation for creating more comprehensive, advanced flexible intelligent manufacturing workshops.

The completion of FAW Moulding’s small parts intelligent processing flexible line workshop achieved multiple industry firsts, resulting in over 20 patent applications:

Top 4 Industry Firsts

NO.1 First automotive panel stamping dies automated processing line

NO.1 First central pre-adjustment station automation unit

NO.1 First automated line achieving rapid robot positioning, quick assembly/disassembly, and replacement

NO.1 First Automatic coupling AGV automated processing line

Looking Forward: FAW Moulding aims to implement a second-phase large item automation project, further advancing intelligent levels in enterprise R&D, production, management, and service in digital development directions.

As a pioneering trendsetter among national automotive brands, FAW China has accomplished notable achievements since its establishment: in 1956, China’s first Jiefang vehicle rolled off the line, ending China’s inability to produce vehicles; in 1958, the first Dongfeng sedan was successfully developed, with the first Hongqi high-end sedan following the same year; in 2005, digital transformation kicked off; the establishment of the industry’s first small parts flexible manufacturing workshop... Behind these continued milestones, achieving China’s first “times” in national automotive industry reflects FAW’s aim to enhance overall competitive strength in the industry, supporting national automotive industrial development, embracing international ambitions, and pursuing the passionate dream of becoming a mould making superpower.

The smart factory construction lies where production, operation, and management data converge. One must focus on the company’s mid-to-long-term development strategies, considering its products, processes, equipment characteristics, and order features to rationally plan the intelligent factory construction blueprint. FAW Moulding’s digital and intelligent transformation journey embodies a process of gradual integration and mutual promotion between information technology and industrialization, with EMAN poised to continue partnering with FAW Moulding, writing a new blueprint for the digital and intelligent transformation and upgrading of car factories together.