EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

The workshop traditionally used manual production management methods, with supervisors arranging production and relying heavily on staff for project management. Crucial information about the workshop resided in the minds of technical staff, which hindered decision-making at the executive level. The state of production factors was not updated in real-time, leading to delays in feedback on questions such as who worked on what task, when, where, how much time was spent, the task completion status, what remains to be done, progress reporting, and expected delivery dates. Due to the complex manufacturing processes, frequent changes in product design, and the complexity of processing, it was difficult to ensure quality across different manufacturing stages. Furthermore, production resources were unevenly distributed.

Intelligent Production Management: Leverage a mold MES system to coordinate resources and planning, implement intelligent management and proactive control, and enable integration and collaboration.

Intelligent Processing: Introduce intelligent programming, on-site logistics, and tooling/fixturing systems, promote semi-automated processing, data collection, and cyber-physical systems.

Automated Workshop: Realize automated processing (CMM/CNC/EDW/EDM), machine tool control, feedback systems, and cyber-physical systems within the workshop.

The objective is to advance smart manufacturing capabilities, achieving informatization, lean processes, and automation across all production stages to build a comprehensive smart manufacturing factory.

Mold Production Management System: Establish SOPs for mold design, manufacturing, and handling exceptions. Implement clear and standardized procedures for mold processing and quality control. Integrate data such as mold orders, materials, and procurement with the company's SAP system for seamless data exchange, reducing redundant data entry and ensuring consistency.

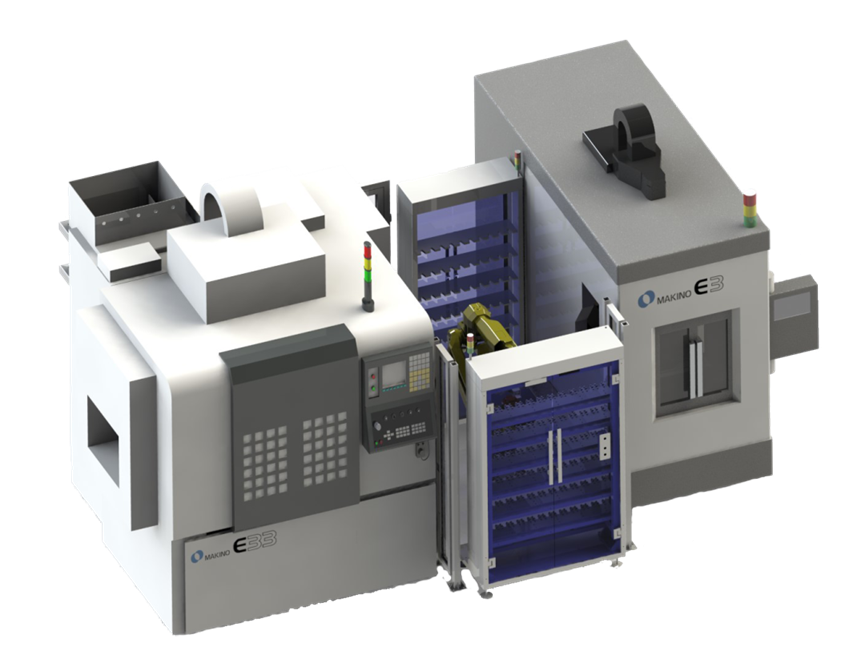

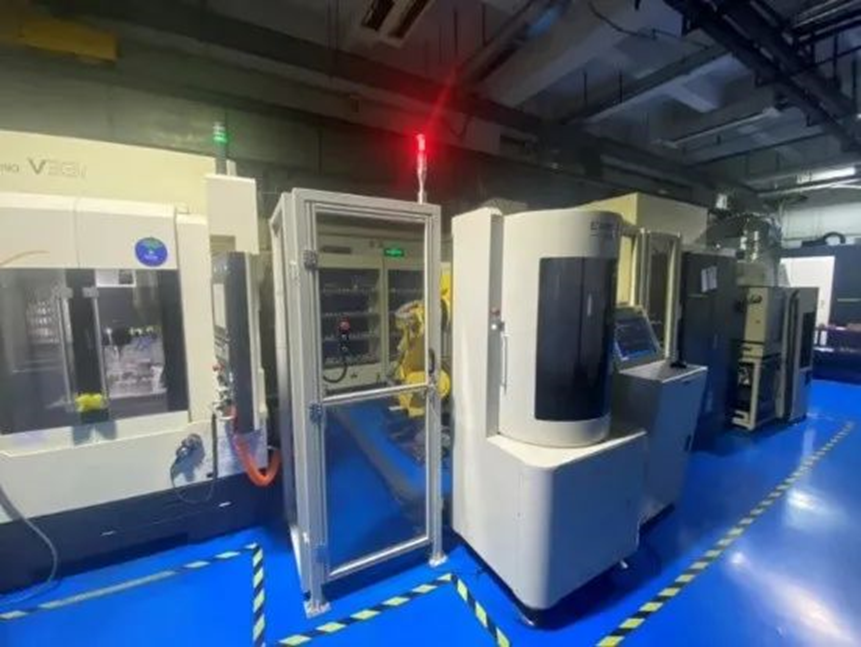

Automated Electrode Processing Unit: Includes one six-axis robot, two CNC machines, and two electrode racks, facilitating low-manpower automated electrode processing under central control system logic.

Automated Electrode Detection Unit: Comprises one six-axis robot, two CMM machines, and two electrode racks, enabling automatic generation of testing programs. The unit offers automated electrode detection, providing lightweight 3D inspection reports that allow quick viewing and parameter modification.

Automated Steel Processing Unit: Utilizes one six-axis robot, two machining centers, two steel racks, and one loading station. Controlled by the EMAN automated processing system, it performs automated steel processing, prioritizing parts based on scheduling plans from the mold MES. It manages online tasks and processing based on precision demands, ensuring production accuracy and timely delivery. The system provides real-time feedback on execution results to the EMAN intelligent manufacturing management system, providing transparent production progress displays.

With the help of EMAN's integrated solution, Ace Mold Hefei Co., Ltd. established a secure, controllable manufacturing control system, providing multidimensional monitoring and analysis of processes, personnel, and quality. This satisfies the demands for refined, automated, real-time, and data-driven management, realizing flexible manufacturing management. While improving production efficiency, the company also enhanced product quality stability. The system's implementation yielded the expected results and became a successful case of smart transformation.