EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

Over the years, Kaihua has utilized intelligent manufacturing as a strategic breakthrough, leveraging automation and smart technologies to become a representative of high-end "Made in China" in the international market.

Since 2018, EMAN has acted as Kaihua's key partner in digital transformation, providing comprehensive digital and intelligent manufacturing services. This support has helped Kaihua maintain strong capabilities and achieve growth against the backdrop of global economic downturns, strict pandemic controls, and rising export costs.

In 2000, Liang Zhenghua, the founder of Kaihua, started Huangyan Kaihua Mold Co., Ltd. with an initial investment of 50,000 RMB. After 20 years of vigorous development, Kaihua has become a leading global provider of plastic mold design, manufacturing, production, and assembly solutions. With total assets of 1.1 billion RMB, it operates three main production bases and encompasses four major business sectors: automotive, medical, logistics, and home appliances. Kaihua has 15 offices across the globe and serves over 300 domestic and international clients, including renowned names like Volkswagen, Mercedes-Benz, General Motors, Dongfeng Nissan, Yanfeng, Adient, Magna, and Bosch. Currently, Kaihua's automotive dashboard molds represent the highest domestic standards and rank among the top three globally in the industry.

In 2006, Kaihua obtained the right to export independently and officially entered the international mold industry competition. As overseas orders increased, Kaihua recognized the urgency for digital transformation. To preserve mold design expertise, improve efficiency, reduce costs, and stabilize quality, Kaihua established its own design standards library, enhancing the standardization of mold designs.

By 2011, Kaihua entered a rapid development phase, completing its institutional process construction and forming a standardized management model across three dimensions—technology, management, and shop floor operations. In 2017, Kaihua astutely identified the mainstream trends of "lightweight, short-cycle, and low-cost" automotive forming technologies, setting the main tone for a smart factory and undertaking a comprehensive digital transformation of its production and management processes.

Kaihua's Commitment to Excellence in Large Injection Mold Manufacturing,to achieve its manufacturing objectives of "high quality, high efficiency, and short cycle times," Kaihua employs a lean management system to oversee the entire production process. Systems such as MES, CRM, ERP, OA, and SCM have been implemented and iteratively updated. Key projects, including the mold MES and supply chain SCM, are managed by EMAN.

In 2018, Kaihua introduced the EMAN Mold MES system. By 2022, to enhance data accuracy, consistency, and system usability, Kaihua upgraded the EMAN Mold MES system once again. This new MES system, built on the previously established data management framework, facilitates seamless data integration across Kaihua’s multiple systems. It enables intelligent integration, helping Kaihua manage raw materials, inventory, data traceability, and quality control more scientifically and efficiently. This integration achieves a high degree of fusion in manufacturing processes, such as production scheduling, quality, procurement, materials management, and warehousing.

Kaihua is dedicated to technological innovation and is recognized as a national intellectual property advantage demonstration enterprise with over 220 patents, including more than 80 invention patents. The company excels in lightweight innovative forming technologies such as "micro-foaming, thin-wall, gas-assisted, and plastics replacing steel," as well as collaborative innovation in product and mold structures like "stack molds, low-pressure injection, in-mold cutting, and paint-free technologies." By delivering high-quality products, Kaihua continuously provides optimal solutions to its clients.

As Kaihua’s digitalization advances, the company is also significantly investing in automation.

As a crucial component of molds, inserts have a complex manufacturing process. Previously, Kaihua's inserts were similar in type but varied in size, which made clamping fixtures complicated and left room for human error during program uploading. Additionally, because inserts require multi-surface machining, traditional three-axis machines could not process them effectively, affecting the overall precision of the workpiece.

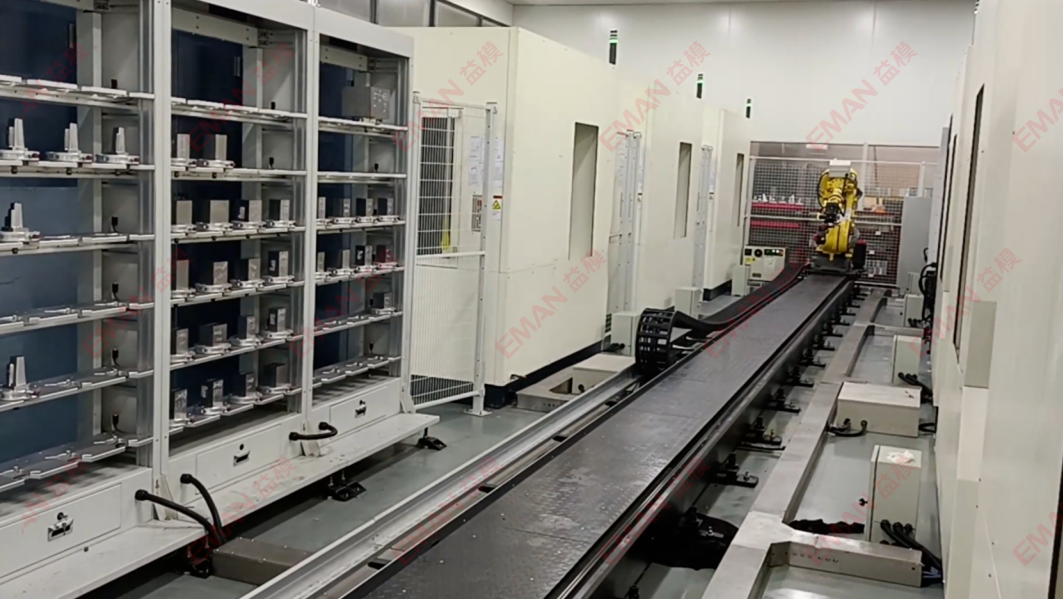

To address existing challenges, Kaihua partnered with EMAN in 2022 to develop a flexible automation line for insert machining, after extensive comparisons and onsite customer visits. Integrating two Doosan machines for rough machining and six Makino five-axis machines for precision machining, EMAN designed a flexible automation track line for Kaihua that combines rough and fine insert machining. The production line features a 148 zero-point positioning system, enabling rapid and precise zero-point location of inserts. It facilitates single-person operation of the production line, with integrated dual-process management. Tasks traditionally requiring manual intervention, such as tool setting, program preparation, tool installation, and rough-to-fine programming, are all managed systematically, achieving a machining precision of 5μm and a machine utilization rate of 95%.

This automation system is seamlessly integrated with the MES production management system, ensuring that foundational data, work order data, process data, programming data, and task planning are consistent and seamlessly integrated. The track line can be directly scheduled to machines via Advanced Planning and Scheduling (APS), automatically analyzing equipment load distribution and estimating part work order delay status. The system operates independently of human oversight, significantly reducing labor intensity and enhancing machining efficiency.

Kaihua, true to its motto of “Speed and Passion,” focuses on quality by introducing advanced intelligent equipment, deploying SAP and MES digital management systems, and establishing flexible production lines. The company partners with over 180 top-tier clients globally and exports premium products to more than 50 countries and regions. By adhering to a customer-centric philosophy, Kaihua has earned unanimous recognition and praise from both domestic and international clients. It achieves counter-trend growth by leading with technological and management innovations and leveraging intelligent manufacturing.

In the future, Kaihua will be driven by its mission to create a better world, upholding core values of “honesty and integrity, trust and respect for individuals, continuous innovation, performance orientation, striving for excellence, and valuing attitude and detail.” With a vision to become a leader in global technology enterprises and a goal of spearheading the global mold industry, the Kaihua Hummingbird team will maintain its speed and passion, extending its innovation across the supply chain and bringing Kaihua’s precision mold products to every corner of the globe. We believe Kaihua will continue to shine brightly with the charm of Chinese intelligent manufacturing on the world stage.