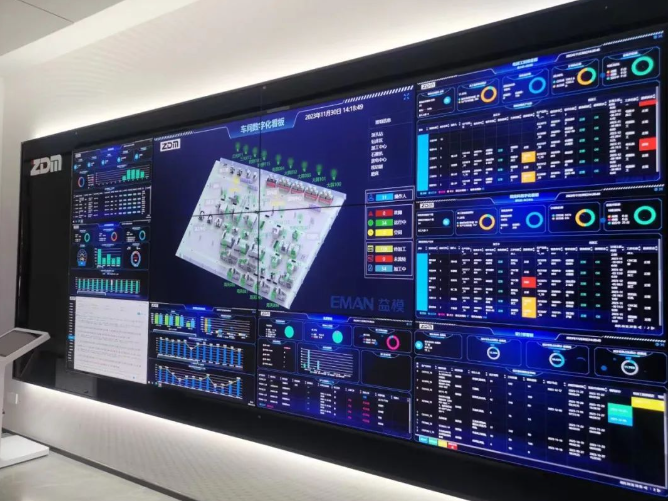

EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

Recently, a project acceptance meeting was held for the Phase I implementation of the Mold MES (Manufacturing Execution System) at Ningbo Zhenzhi in collaboration with EMAN. Attended by leaders, project teams, and business teams from both sides, the meeting concluded with the successful launch and acceptance of the Phase I project.

Leveraging EMAN's Mold MES system, Ningbo Zhenzhi's mold factory has achieved real-time dynamic scheduling, progress tracking, delivery management, equipment management, cost management, and quality control objectives, significantly enhancing its production management model and level. According to assessments by Ningbo Zhenzhi, the implementation of the Mold MES can increase production efficiency in the mold workshop by 30%, shorten mold delivery times by 20%, improve equipment utilization rates by 15%, and reduce management costs by 30%.

Specialized National Champion of Ultra-Large Die Casting Molds Pursues Digital Transformation and International Expansion

Ningbo Zhenzhi Mechanical & Mold Co., Ltd. (referred to as Ningbo Zhenzhi), established in 1999, specializes in the R&D and manufacturing of large, precise die casting molds. It is one of the leading and fastest-growing professional die casting mold manufacturers in China, holding a prominent market share.

Zhenzhi's product portfolio is entirely focused on die casting molds for automotive components, including molds for new energy vehicles, body structures, powertrains, and valve steering systems, with an annual production capacity of 300 molds. Notably, molds suitable for die casting machines with capacities over 6000 tons are produced at a rate of over three molds per month, with new molds accounting for 70% of production.

Known for its high-quality development capabilities, Zhenzhi has established a robust brand reputation, with its molds being welcomed domestically and exported to Germany, France, Italy, Japan, Southeast Asia, and other international markets. The company is part of the supply chain for prestigious global new energy vehicle mold suppliers and included in the mold supplier network of Magna, a Fortune Global 500 company. It has been repeatedly honored as an "Annual Excellent Supplier" by leading industry players both domestically and internationally.

The rapid growth of the new energy vehicle market and the demand for lightweight auto structures and integrated large die castings present significant opportunities and challenges for Ningbo Zhenzhi. To address trends such as shorter product delivery cycles, increased design changes, and heightened quality demands, as well as to gain a competitive edge in international markets, Ningbo Zhenzhi has embarked on a Mold MES project in collaboration with EMAN.

Proactive Engagement, High Execution, and Smooth Project Launch

Throughout the project, Ningbo Zhenzhi demonstrated outstanding teamwork across leadership, team leaders, and frontline users:

>Leadership: High attention and excellent internal and external coordination;

>Team Leaders: Set an exemplary role model, supervising system utilization;

>Frontline Employees: Strong sense of ownership in addressing operational issues and communicating requirements, actively inquiring, learning, and increasing their understanding and application of the system.

The collaborative efforts of both parties have resulted in the project’s successful launch and acceptance. Now, in areas such as orders, processes, planning, and production, Ningbo Zhenzhi is significantly revitalized:

Business Management: Unified order management standards prevent unstandardized and error-prone production directive issuance, greatly improving efficiency and transparency.

Process Planning: Real-time online management of new, repair, and scrap rectification processes enhances process transparency and traceability, strengthening process-guided production models.

Onsite Management: System-enabled traceability and control of human-machine-material processes, with real-time visibility of each component's processing status.

Planning Management: Intelligent real-time dynamic scheduling handles order changes and abnormalities efficiently, ensuring flexibility and control in production and guaranteeing order delivery times.

Ningbo Zhenzhi has established a production management model centered on planning management and process-guided production, fully leveraging workshop resources and capacity, resulting in significant improvements in quality, mold delivery times, employee efficiency, and equipment utilization rates.

Continuous Optimization and Progress – The Never-Ending Journey of Digital Transformation

At the acceptance meeting, Zhang Qunfeng, Chairman and General Manager of Ningbo Zhenzhi, expressed high regard and recognition for EMAN, stating:

"The project's successful launch and acceptance are attributable not only to EMAN's strong capabilities in Mold MES but also to their comprehensive and attentive delivery services. We appreciate EMAN's team's strong support.

In traditional manufacturing, the only path forward is transformation and upgrading. The project acceptance marks a fresh start, not an end, and Zhenzhi will continue to strengthen its foundation by deepening system applications and continuously optimizing and advancing. We look forward to broader, deeper, and closer collaboration with EMAN as we create a benchmark for cooperation and step into a new digital future."

The successful acceptance of the Zhenzhi project reaffirms EMAN's industry position. By embracing "digital transformation and upgrading," Ningbo Zhenzhi is advancing rapidly towards high-quality development. As a digital partner, EMAN will accompany Ningbo Zhenzhi throughout this journey, offering exceptional technical support and services, helping reduce costs and increase efficiency, and delivering quantifiable value benefits to support its expansion onto the larger international stage.