EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

The Advanced Planning and Scheduling (APS) system serves as a crucial tool for enhancing precision in production planning and improving efficiency. It has been increasingly adopted by manufacturing enterprises with high expectations. However, many companies encounter significant obstacles during the APS implementation process, resulting in unmet expectations. Why do companies find it challenging to utilize APS effectively? What makes the implementation difficult?

This article aims to assist you in addressing the challenges of APS selection and implementation by discussing common issues faced by manufacturing enterprises, key factors for successful application, and typical practice case studies.

>>Overlooking Strategic Planning and Goal Setting:

Many companies introduce APS without thoroughly analyzing their specific needs and the unique nature of their business processes. This lack of a clear strategic plan and specific goals leads to system selection and customization that deviates from actual requirements, failing to meet the unique production scheduling demands. Additionally, the absence of scientific and comprehensive implementation planning and strategies leads to frequent issues and project delays.

>>Overlooking the Importance of Data:

The efficient operation of APS depends on accurate and complete data support. Many companies face data silos, with poor data flow between systems, making it difficult to obtain high-quality key data needed by APS. This weak data foundation and system integration barriers significantly impact the overall effectiveness of the APS system.

>>Overlooking POC Verification for APS:

Each manufacturing enterprise has unique production processes. Without scenario verification (POC), the APS system may not fully adapt to the specific business processes of a company, leading to discrepancies between production plans and actual production, and posing other potential risks.

>>Overlooking Organizational Change Management:

Without proper cognitive training and change management within the organization, front-line employees may resist new systems, perceiving APS as a disruption to work habits and an additional burden. Furthermore, APS implementation is typically a "top management" project. A lack of necessary support and key decisions from management can hinder system promotion.

The main reasons for the difficulty in APS application include insufficient demand understanding and implementation planning, weak data foundation and system integration barriers, personnel training and cognitive obstacles, and inadequate continuous optimization and adaptability adjustments.

Based on numerous successful application cases, EMAN has discovered that real, accurate, and timely data, combined with extensive practice and intelligent algorithms for complex scenario optimization, can directly translate APS application into practical, high-efficiency executable plans.

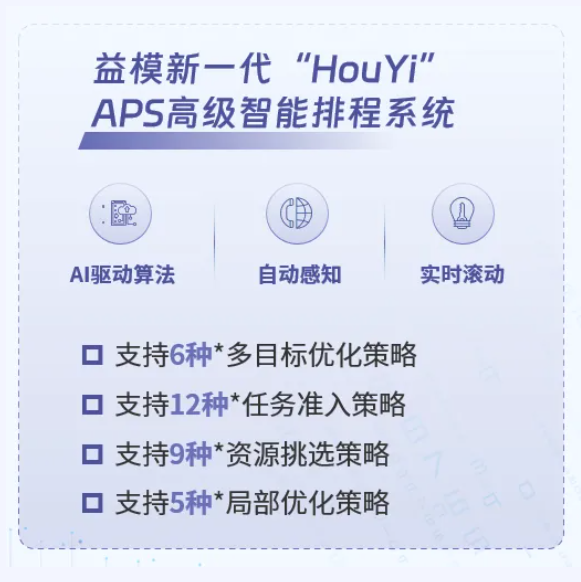

EMAN's New Generation "HouYi" APS Advanced Smart Scheduling System

EMAN's new generation "HouYi" APS advanced smart scheduling system offers comprehensive analysis and practice for the characteristics of discrete, small-batch, and multi-process production and their diverse business scenarios. After conducting over 200 factory surveys and implementations in industries necessitating flexible production such as molds, equipment, military, automotive, and home appliances, EMAN has launched the "HouYi" APS system through continuous iteration in digital modeling and intelligent algorithms.

Leveraging nearly 20 years of industry accumulation in modeling strategies, EMAN's new generation "HouYi" APS system breaks the limitations of traditional iterative algorithm platforms, achieving a qualitative leap in algorithm speed and efficiency.

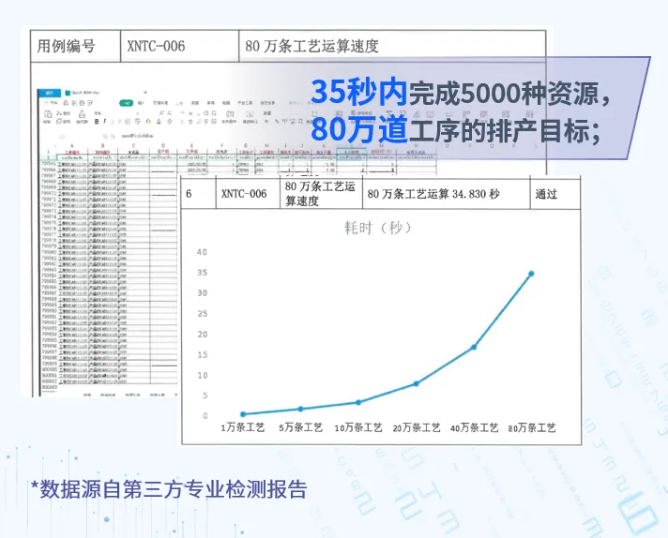

According to authoritative testing reports, the EMAN's new "HouYi" APS system completes complex computational tasks involving 5,000 devices and 800,000 processes within 35 seconds. This algorithm speed is equivalent to running a full marathon (42.195 kilometers) in one minute, significantly surpassing other APS systems in the market.

Typical Application Case: Zhuhai Gree Daikin Precision Mold Co., Ltd. (Gree Daikin)

Established in 2009 as a joint venture between Zhuhai Gree Electric Appliances and Japan's Daikin Industries, Gree Daikin is a large-scale precision mold company focused on precision injection molds, sheet metal stamping molds, research and development, manufacturing, sales, and after-sales service. With over 450 employees and more than 200 CNC machines, Gree Daikin operates in fields including home appliances, automotive parts, consumer electronics, and medical devices.

With continuous business expansion, Gree Daikin faces urgent needs for improved production management efficiency, shortened production cycles, and personnel efficiency. To address these challenges, Gree Daikin decided to introduce EMAN's APS to comprehensively optimize production processes.

>>Challenges Faced:

In the project's initial phase, with more than 200 CNC machines and complex scheduling scenarios involving numerous molds, workpieces, and processes, Gree Daikin demanded high speed and accuracy from the smart scheduling system:

Workshop Production: Efficiently schedule approximately 200 sets of molds, 10,000 workpieces, and 100,000 processes to ensure smooth production.

Capacity Simulation: In simulated scheduling, handle approximately 900 sets of molds, 50,000 workpieces, and 500,000 processes to evaluate production potential.

>>Objectives and Execution Rules:

Through multiple rounds of communication, discussions, and optimization of production processes, EMAN and Gree Daikin jointly established objectives and execution rules for APS application:

APS Objectives:

Optimization Rules:

Minimize Order T1 Delays: Prioritize timely delivery of important orders.

Maximize Equipment Utilization: Improve equipment usage efficiency through smart scheduling.

Non-interference of Primary and Backup Resources: Flexibly schedule resources to avoid idle time.

Fastest Completion of Parts and Priority for Urgent Parts: Shorten the parts processing cycle and enhance response speed.

Prioritize Complete Parts Processing: Accelerate assembly processes and reduce finished product delivery time.

Constraint Rules:

Allocate limited and unlimited resources based on process characteristics.

Synchronize production of electrodes and steel parts to optimize production processes and shorten cycles.

Reserve programming time for task modification.

Ensure precision and safety in production through process constraints with equipment size, accuracy, and human skills.

Besides system rules, Gree Daikin has established a set of APS implementation methodologies:

>>Value and Benefits:

By introducing EMAN's APS system and establishing scientific implementation methods, Gree Daikin has achieved significant improvements in production management efficiency, production cycles, and personnel efficiency, laying a solid foundation for sustainable development competitiveness.

Order Type Growth: Injection and sheet metal orders increased by 12% compared to 2023, significantly enhanced market demand responsiveness.

Production Cycle Reduction: The average production cycle for the injection sector shortened by 37.7%, and for the sheet metal sector by 28.1%, greatly enhancing production efficiency.

Significant Personnel Efficiency Increase: The PMC (Plan Management Center) team was streamlined from 9 to 6 people, achieving a 33.3% personnel efficiency increase, further optimizing the cost structure.

Work Hour Deviation Control: By regularly analyzing and adjusting process evaluations, overall work hour deviation was controlled within ±10%, significantly enhancing fine management levels.

The implementation and application of APS is not achieved overnight; enterprises need to improve technical training, break data silos, optimize business processes, and strengthen management support to significantly improve production planning and efficiency.

If you are facing challenges in APS application or are interested in EMAN's APS technology and products, please feel free to contact us