EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

On February 28th, EMAN held its first online live course of 2020, in conjunction with Makino. The event gathered over 50 sales and marketing professionals from both Makino and EMAN to discuss the future of mold automation and explore mold automation solutions better suited to the evolving needs of mold enterprises.

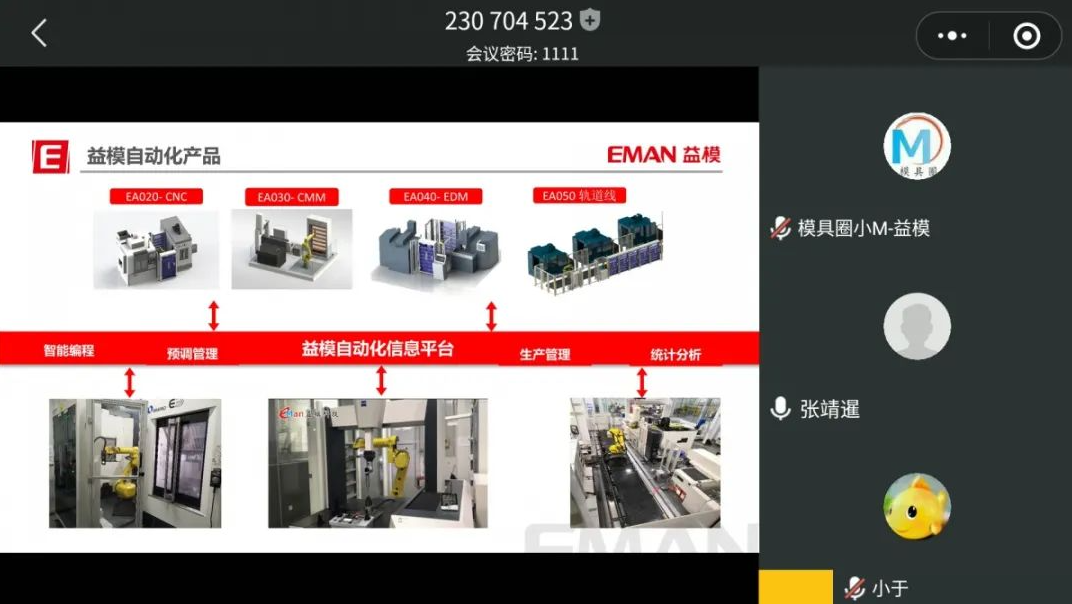

EMAN's Automation Department Manager, Zhang Jingxian, provided an in-depth explanation of EMAN's mold automation products. He covered topics such as EMAN's automation product philosophy, the benefits of automating CNC/EDM/CMM equipment, and the collaboration between EMAN and Makino. This strong alliance and sincere cooperation have led to successful implementations and services for leading mold enterprises such as Huawei, Donglei, Baoxun, Founder, Dongjiang, and Chongqing Kaiwu. The automation lines included formats like CNC cells, CMM cells, EDM units, and track lines.

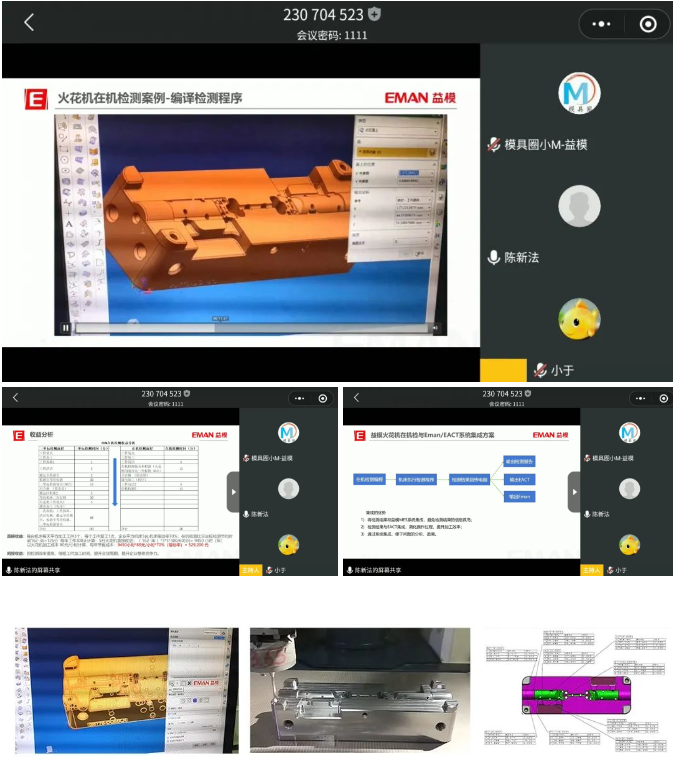

EMAN's Product Manager for Intelligent Design and On-Machine Inspection showcased the EDM on-machine inspection solution offered by EMAN. Manager Chen presented successful case studies of this solution in collaboration with Makino, as implemented for Gree Electric's precision molds and Dongguan Tongjie Precision Molds. The EMAN EDM on-machine inspection solution effectively reduces workpiece handling, enables coordinate measuring machine (CMM) inspections, and allows for real-time problem detection. This approach in mold automation significantly saves inspection time and enhances machine utilization rates for enterprises.

Following the presentations, participants engaged in discussions on key concerns, fostering mutual understanding and recognition. Moving forward, both parties will continue to deepen their efforts in the field of mold automation, continuously advancing the automation capabilities of mold enterprises and promoting their healthy development.