EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

On October 17–18, Makino Machine Tool (China) Co., Ltd. successfully held the 2024 Makino Technology Exhibition under the theme "Innovation Without Limits, Leading the Future" at its Kunshan factory in Suzhou. This grand event brought together manufacturing leaders, engineers, intelligent manufacturing experts, and technical professionals to explore future trends and innovative applications in intelligent manufacturing. As an invited guest, EMAN Technology actively participated and witnessed this feast of intelligent manufacturing.

At the Makino Technology Exhibition, as a long-term partner of Makino, Lu Fanrong, General Manager of EMAN Technology’s East China Region, delivered an insightful speech titled Digital Planning and Implementation Cases for Mold Factories, systematically introducing EMAN’s digital solutions and products in the mold field.

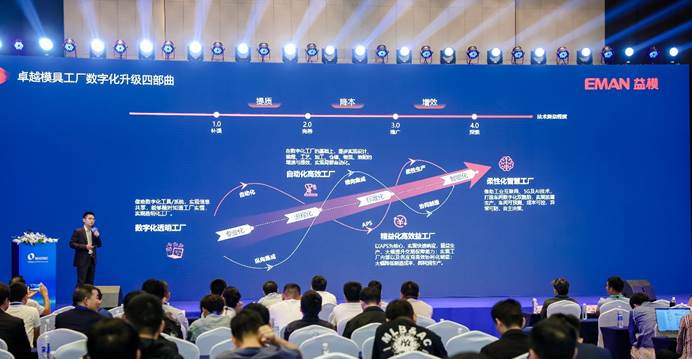

(1) Digital Transformation Path: Parallel Development from Transparency to Intelligence

In his speech, General Manager Lu detailed the entire process of planning and implementing enterprise digital transformation. Starting from building a transparent digital factory, progressing to an automated high-efficiency factory, then to a lean high-benefit factory, and ultimately achieving a flexible intelligent factory, this parallel (rather than linear) development path integrates big data, IoT, AI, and other technologies. It has been gradually implemented in EMAN’s customer practices, helping enterprises achieve leaps in production efficiency.

(2) Whole-Factory Planning for Molds: Comprehensive Coverage of Intelligent Manufacturing Needs

At the event, General Manager Lu showcased EMAN’s rich product matrix, including the Mold Intelligent Design System (EMoldDM), Mold Production Management System (EMan), Flexible Automated Machining System (EAtm), Mold Supply Chain Collaboration Platform (ESrm), and In-Plant Intelligent Warehousing and Logistics (EAgv, EAsRs). These products fully address the entire lifecycle needs of mold enterprises, from design and production management to outsourcing, machining, and warehousing logistics. By introducing intelligent whole-factory planning and layout for mold enterprises, EMAN provides precise support and integrated transformation ideas for efficient enterprise transitions.

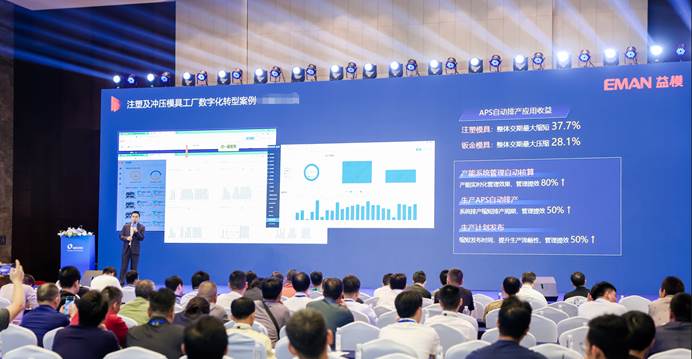

(3) Rich Practical Cases: Validating Intelligent Manufacturing Strength

General Manager Lu also shared multiple success stories, covering automotive parts molds, home appliance molds, injection molds, and stamping molds, as well as enterprises ranging from SMEs to large groups, such as Elite Molds, Gree Daikin, Weida Machinery, Biyoute, and Kaihua Molds. By sharing the whole-factory planning, digital and automated implementation, and results of these enterprises, EMAN not only validated the effectiveness and practicality of its solutions but also provided valuable references for other enterprises.

The successful hosting of the Makino Technology Exhibition provided a platform for exchange and learning among peers in the intelligent manufacturing field and offered insights for the future development of intelligent manufacturing.

Looking ahead, EMAN Technology will continue to uphold its customer-centric and innovation-driven R&D philosophy, launching more high-quality intelligent manufacturing solutions to support the transformation and upgrading of mold enterprises. EMAN also looks forward to collaborating with more mold enterprises and partners to jointly promote the prosperity of intelligent manufacturing and create a new future for intelligent manufacturing!