EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

Amid China's new dual-circulation development paradigm and the Belt and Road Initiative, a new global cooperation blueprint is extending its reach across industries, prompting more Chinese software companies to "go global". How did a leading company in the global precision plastic injection molding engineering field ignite a multinational collaboration with EMAN?

From Zhang Qian's pioneering "journey to the Western Regions" to the maritime Silk Road of the Tang, Song, and Yuan Dynasties, and then to Zheng He's seven voyages during the Ming Dynasty, generations of "Silk Road travelers" have forged bonds of cooperation between the East and West.

In this context, EMAN has expanded its reach beyond domestic enterprises, securing international clients in countries such as Vietnam and Germany. Recently, EMAN marked another step in its internationalization strategy by partnering with its first client in Singapore, OMNI. Singapore, renowned as the "Lion City," and Wuhan, known as the "River City," are separated by over 3,400 kilometers. One is a global leader in precision plastic injection engineering, the other a seasoned provider of manufacturing system solutions for over 15 years. How did these two entities forge a cross-border partnership?

A Noteworthy Beginning

One afternoon in 2018, an email popped up on a market staff member's computer at EMAN, initiating an inquiry into EMAN's mold Manufacturing Execution System (MES) from a representative in Singapore. This inquiry came from OMNI MOLD (OMNI), established in 1989 and part of Sunningdale Tech Ltd. Through strategic acquisitions facilitated by governmental support, Sunningdale Tech has grown into Singapore's largest mold manufacturing group, with subsidiaries in over ten countries worldwide. OMNI boasts over 3 million square feet of production facilities and more than a thousand injection molding machines, producing up to 2,000 molds annually.

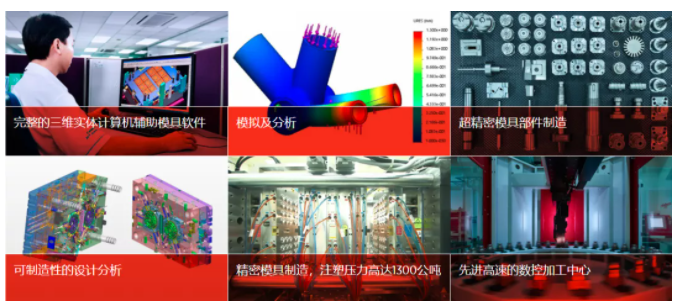

OMNI's outstanding capabilities

Within its expansive corporate lineage, OMNI specializes in high-performance molds, particularly excelling in ultra-precision, high-complexity, and multi-cavity injection molds. The company operates across sectors such as pharmaceuticals, healthcare, nutritional packaging, information technology, office automation, automotive, and consumer electronics. Recognized globally for its capability in crafting challenging molds, OMNI stands as one of the most advanced ultra-precision mold manufacturers in the industry.

Proactive Adaptation and Readiness

Throughout its 30-plus year history, OMNI has persistently pursued lean management to address market challenges, integrating ERP systems years ago with expert in-house teams managing finance, human resources, and material administration adeptly.

OMNI Mold Products

However, even with ERP systems in place, OMNI's leadership observed disparities such as uneven workload distribution across workshops, leading to operational inefficiencies. Driven by intensifying market competition and increased demands from high-end clients regarding quality, cost, and delivery, OMNI sought a breakthrough: intelligent manufacturing.

OMNI workshop reality

Familiar with the principles of intelligent manufacturing, OMNI approached this transition with strategic caution, realizing that while ERP systems support overarching operations, they fall short at the shop floor level in detailed process management crucial for mold manufacturing. This insight led OMNI's leadership to seek an MES system tailored for mold workshop management. However, recognizing point solutions as inadequate for their long-term vision, OMNI sought a strategic partner capable of promoting lean production and comprehensive cost-efficiency enhancements.

OMNI at international exhibitions

Partnering with EMAN for Advanced Manufacturing Solutions

For two years, OMNI scoured Singapore for a fitting MES supplier, but to no avail. A recommendation from an employee in their Guangdong, Zhongshan facility introduced them to EMAN, initiating the collaboration proposal. Across multiple online consultations, on-site visits to EMAN’s headquarters and client sites in Shanghai and Ningbo, and reciprocal visits to Singapore, EMAN demonstrated its technical expertise and sincere commitment through vertical specialization in the mold domain, ultimately winning OMNI’s confidence.

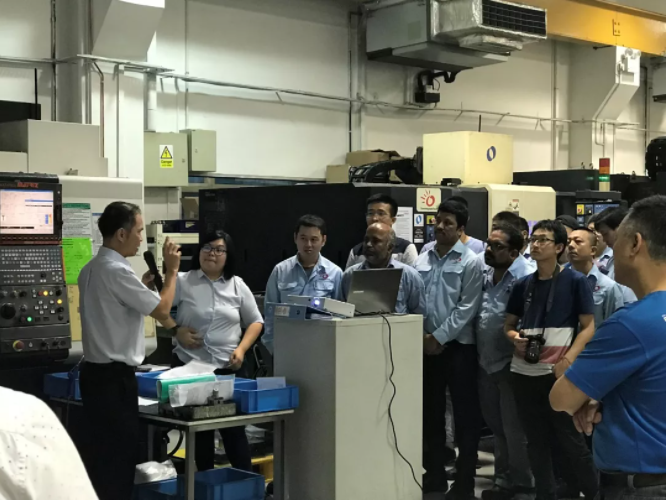

OMNI project senior leaders visit Wuhan Yimo headquarters

OMNI project senior leaders visit Yimo customer site

Once collaboration was on the horizon, EMAN deployed a dedicated project team, commuting between Wuhan and Singapore, to deliver customized solutions. Though OMNI had been inclined towards adopting smart management tools, their lack of a coherent, integrated management ideology posed a hurdle. EMAN introduced OMNI to a comprehensive mold lifecycle management approach via its EMan system, capable of end-to-end management from order receipt to delivery. With robust integration capabilities, EMan enables vertical data assimilation across departmental operations, achieving seamless digital and transparent production processes by dismantling silos.

Conceptualize a factory as a living organism, and envision EMan as the central nervous system, coordinating messages from across factory operations akin to how the human nervous system orchestrates body movements. EMan integrates systems and links base-level equipment, relaying information to users. This orchestrates every element of production, from scheduling and statistics to cost control and inventory management, enabling holistic, closed-loop management.

EMan project kickoff meeting on-site

A simple scenario: the EMAN mold smart manufacturing system allows shop floor workers to track material timelines from machine setup to completion and process transition, documenting processing duration and aiding in optimization to minimize wait times, thus boosting productivity and expedient deliveries.

The Future of Domestic Software on the Global Stage

Today, market sectors are diverse and demand unique software solutions, extinguishing the era of one-size-fits-all applications like CAD and PLM. This diversity presents an opportunity for Chinese software. The growing recognition of industrial software's crucial role in global development, alongside supportive national policies, suggests a promising trajectory for domestic software to address industry-specific pain points, driving innovation and achieving international reach. Despite the challenging path ahead, EMAN remains steadfast, embodying the indomitable spirit of navigating uncharted waters, poised to set sail into the expanses of the global market.

EMan project kickoff meeting photo