EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

How to Configure Hardware for Automated Production Lines: Key Insights to Avoid Being Misled

To reduce labor dependency and build unmanned factories, coupled with the wave of intelligent manufacturing, more companies are increasingly investing in automated production lines to ensure seamless production and improve efficiency.

However, the journey of transformation and upgrading is not always smooth. Many companies find that their automated lines do not achieve the expected "labor-saving" effect and instead become a dilemma. Due to the high and complex demands of equipment adjustment, maintenance, and repair, coupled with the need for dedicated management personnel, any delay in service response from suppliers can halt operations, turning the line into a bottleneck rather than a booster.

Why do automated lines with substantial time and financial investment have such issues? When choosing automation suppliers, manufacturing companies have two primary options. Some opt for machine tool manufacturers alongside their automation suppliers; others rely on machine tool providers and specialized automation line manufacturers for system integration. With industrial firms urgently needing automated lines, numerous automation equipment and software companies have emerged, yet their quality varies widely. Some attract enterprises with low prices but compromise on hardware, leaving companies—often with insufficient automation understanding—struggling to discern quality. As a result, firms may be tempted by the apparent cost advantages, unaware that automated lines differ from standalone software services due to their inclusion of both hardware and software, where performance often is proportional to price.

When buying a smartphone, we consider various parameters, but ultimately, system experience determines customer retention. This principle applies to automation workshops: hardware sets the baseline, software defines the ceiling, and only balanced advances in both make for a qualified automated production line.

We’ll delve into choosing a reliable automation vendor, focusing on both hardware and software aspects. Today, we address hardware considerations to guide you in making informed choices. Take note of the following key aspects!

High-Quality Essential: Ensuring Efficient Production

Focus Area 1: Opt for Brand New Robots

In automated production lines, robots (or robotic arms) execute tasks by following direct commands or pre-programmed routines, characterized by retracting, rotating, and elevating actions to precisely target points in a two- or three-dimensional space. Their significance cannot be overstated.

Industrial robots generally achieve motion accuracy below 0.1 mm in repetition and can extend several meters. To cut costs, some vendors opt for refurbished robots, which suffer from worn precision, aged electrical components, and deteriorated mechanical transmission structures. During implementation, it is advisable to use only brand-new robots to ensure high performance as a reliable assistant. Testing motion accuracy, inspecting wear, and requesting original after-sales certificates are ways to confirm the robot's newness.

Focus Area 2: Choose Branded Electrical Communication Modules

Electrical communication modules serve as connectors for transmitting various signals necessary for achieving automated and information-driven smart factory systems. Many vendors use custom IO control boards, whose stability and after-sales support are uncertain. The proper approach involves employing standard professional-brand communication modules for best stability and assurance.

Safety First: Protecting the Initial Line of Defense

Automation hardware includes numerous electrical facilities and dense wiring networks, making proper selection and installation critical for safety.

Focus Area 3: Secure Installation of Control Button Boxes

Control button boxes start machines and involve operational safety. Inadequate installation compromises electrical line safety. Secure fixing methods and status indicator lights significantly reduce accident risks.

Focus Area 4: Durable Shelving Materials

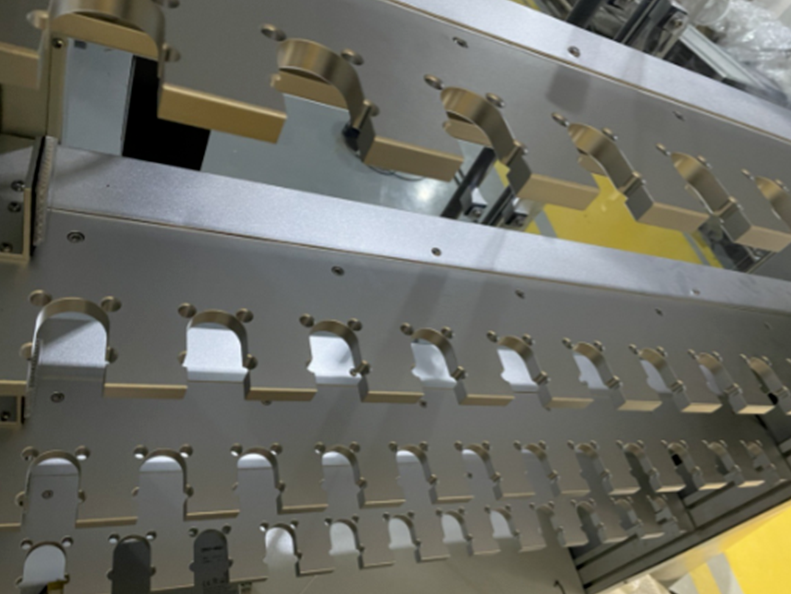

Shelves used for storing parts require robust materials. Yet, many automation vendors use thin, bent stainless steel plates, risking deformation and robot collision over time. Top-tier vendors provide shelves with 10 mm thick aluminum components for high precision, strength, and resilience.

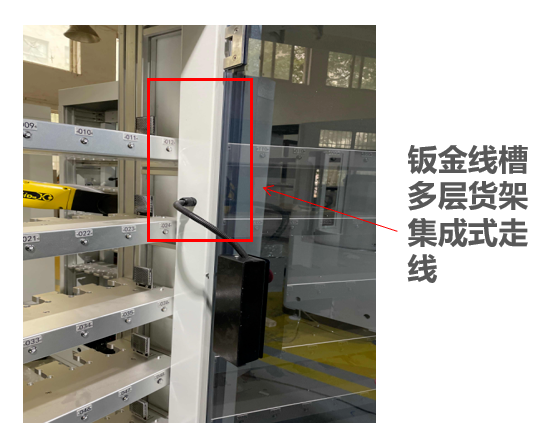

Focus Area 5: Use Enclosed Metal Ducts for Wiring

Wiring routes are vital akin to a production line's circulation system. As with household wiring, many vendors exploit gaps using low-quality materials like plastic ducts. Premium vendors employ enclosed metal ducts, ensuring safety and durability, seamlessly integrating with the shelving for a cohesive appearance.

High Aesthetic: Enhancing the Winning Edge

Bonus Aspect: Visually Appealing Shelving

Automated workshops showcase factory modernization and digitalization, critical during client and peer visits. While standard metal racks suffice, aiming for an impressive client experience and securing orders is more achievable with frameless, laser-cut LED logo shelves, setting a high standard emulated by industry peers.

Comparatively, automated lines function as a well-coordinated sports team, with high-quality equipment and players (hardware) plus an excellent coach (software system integrator) key to overall success.

EMAN’s hardware solutions surpass industry standards, addressing diverse product types, production volumes, and manufacturing processes. Providing CNC automation units (including steel part automation units), CMM automation units, EDM automation systems, and automated systems for mold/multi-variety small batch part processing, EMAN has delivered nearly 100 automated lines successfully, with expertise in offering comprehensive smart manufacturing solutions centered around automation for leading industry enterprises. Future discussions will focus on selecting automation line software vendors—stay tuned for continuous insights and shared expertise.