EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

Recently, EMAN completed a strategic financing round of nearly 100 million yuan, led by Shenzhen Capital Group and co-invested by Rongyu Capital. The funds from this financing are set to be primarily utilized for product development, marketing promotion, and talent acquisition to further solidify EMAN's advantage in discrete manufacturing industrial software and flexible production intelligent manufacturing solutions.

About Wuhan EMAN Technology Co., Ltd. (EMAN)

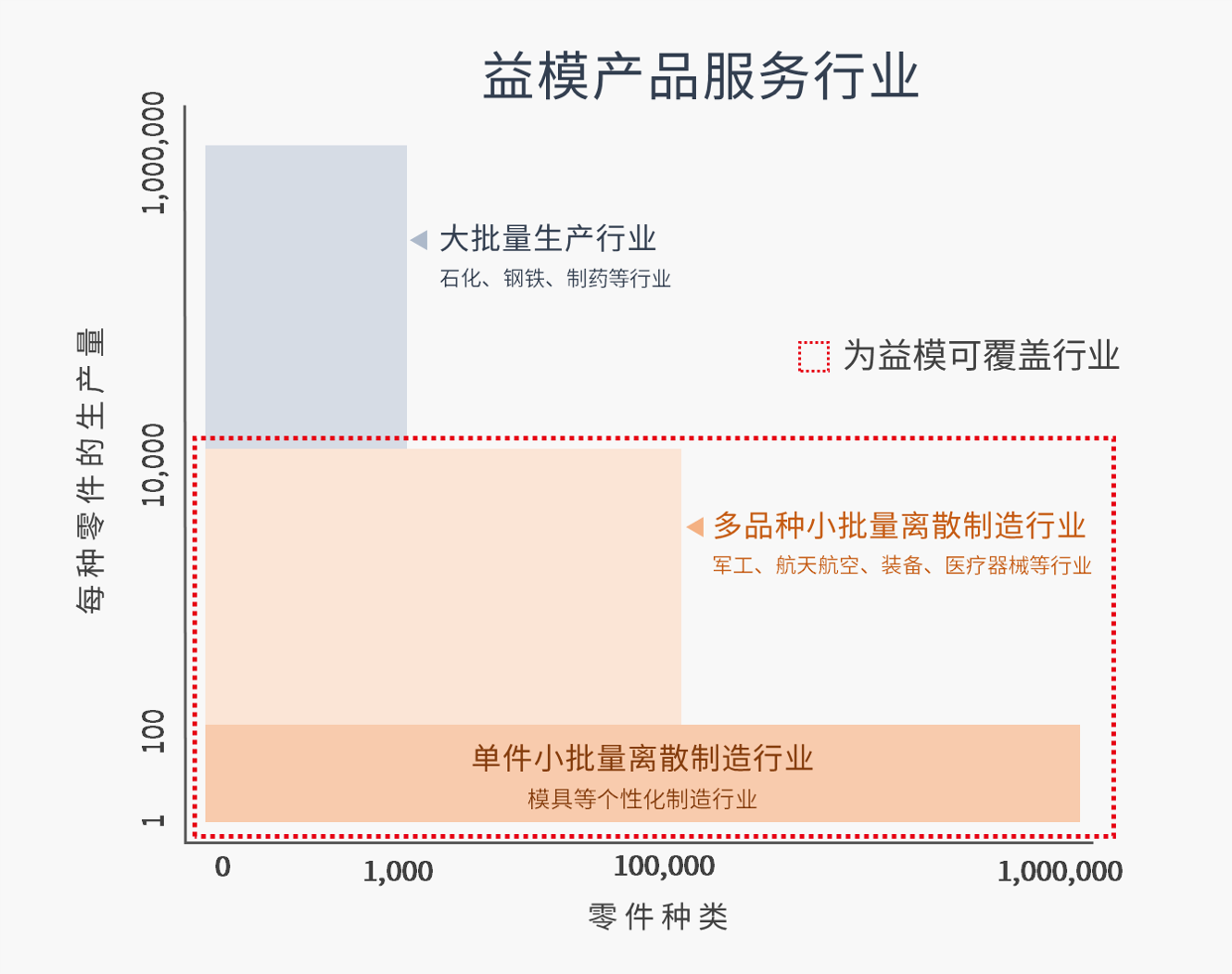

Founded in 2006, EMAN's founding team originated from the State Key Laboratory of Material Forming and Die Technology at Huazhong University of Science and Technology. EMAN is a provider of industrial software and flexible production intelligent manufacturing solutions, owning over 120 independently owned intellectual properties, and has received more than 50 awards including the First Prize of Scientific and Technological Progress in Hubei Province, the First Prize of Scientific and Technological Progress in the Machinery Industry, and the First Prize of the China Industry-University-Research Cooperation Innovation Achievement Award. The company has delivered comprehensive manufacturing operation management (MOM) solutions, including digital production management systems (MES), advanced scheduling systems (APS), flexible manufacturing systems (FMS), and in-plant intelligent warehousing logistics (AS/RS) to more than 600 discrete manufacturing plants in sectors like mold making, equipment, automotive, home appliances, electronics, and medical devices. These solutions have aided these plants in transitioning from "single-variety mass production" to a "multi-variety, small-batch, flexible, and efficient production model" in digital and intelligent manufacturing.

Two Decades of APS Intelligent Scheduling Technology Leadership in Mold Production Control Software

Molds are often referred to as the "mother of industry," with 60% to 80% of parts in major manufacturing industries like automotive, home appliances, electronics, and medical devices relying on mold forming. However, mold enterprises are typical examples of order-based, random-arrival, small-batch discrete manufacturing, characterized by fragmented and random production. For instance, a mold company with 1,000 employees may simultaneously need to schedule hundreds of thousands of process tasks across hundreds of machines, with over 30% of tasks being last-minute insertions. Manual scheduling struggles to achieve optimal coordination, making digital transformation to enhance production efficiency notably more challenging than in industries with single-variety, large-batch production.

In 2006, the EMAN team tackled technological challenges within mold companies, successfully developing a domestic mold intelligent production management software centered around the APS intelligent scheduling algorithm. Using this system, mold companies can schedule hundreds of thousands of processes within seconds, achieving efficient and intelligent optimized scheduling. In scenarios with frequent unpredictable events, it maximizes internal production capacity, significantly improving equipment utilization rates and on-time delivery rates.

In terms of market presence, thanks to its robust product technology, EMAN's mold intelligent production management software has been successfully applied in hundreds of mold manufacturing enterprises, comprehensively covering main mold types like injection molds, stamping molds, and die-casting molds. According to open data from the China Mold Industry Association, 87.5% of the key large precision injection mold backbone enterprises in China and 70% of the top ten die-casting mold enterprises collaborate with EMAN, securing a leading market share. In 2021, EMAN led the formulation and publication of China's first digital capability assessment standard for the mold industry. In 2022, EMAN was featured on the Ministry of Industry and Information Technology's list of "Outstanding Industrial Software Products" as the sole representative in mold production control software.

Building upon its success in the mold industry, EMAN has expanded its coverage comprehensively in the discrete manufacturing field, extending its product matrix to downstream mold component sectors and military/processing/equipment enterprises. This includes benchmark projects in top-tier domestic and international companies across industries like automotive and parts, home appliances, electronics, military, new energy, semiconductors, medical devices, and packaging, such as FAW, BYD, Magna, Aptiv, Midea, Gree, China North Industries Group, Aerospace Electrical, Jincheng Shares, Pioneer Semiconductor, Zhengtian Medical, and Berry Global.

Decades of honing flexible automation technology help the discrete manufacturing industry achieve intelligent manufacturing

As the diverse demands from discrete manufacturing clients continue to increase, production models are shifting from mass production to multi-variety, small-batch production, characterized by a wide range of products, small batch sizes, complex production processes, and heavy reliance on human labor. Thus, companies face challenges such as tight delivery times, low product quality consistency, inefficiency, and difficulties in hiring and employing skilled workers, creating an urgent need for digital transformation and upgrading. However, achieving smart manufacturing under a flexible production model in discrete manufacturing requires integrated software and hardware solutions, which were previously monopolized by leading international firms.

In 2012, based on future trend assessments, EMAN invested significantly in development, launching a comprehensive soft-and-hard integrated flexible production smart manufacturing solution that included manufacturing operation management systems, advanced automated scheduling systems, flexible automated production lines, and in-plant intelligent logistics. After a decade of continuous iteration and upgrades, it now aligns with and surpasses international advanced standards and has been implemented in over 100 workshops within mold industries featuring single-piece small-batch production and versatile small-batch aerospace, military, equipment, medical devices, and precision components discrete manufacturing enterprises - exhibiting vast market potential. In 2022, EMAN's "Industrial Internet-based Flexible Automation Production Management APP Solution" was shortlisted in the Ministry of Industry and Information Technology’s "Outstanding Industrial Internet APP Solutions."

Emphasizing Long-term Strategy and Professionalism, Awaited by Capital with Anticipated Prospects

EMAN Chairman Yi Ping stated:

"China's manufacturing sector, hosting the most comprehensive global production categories, provides rich application scenarios for industrial software development. By staying focused, accumulating experience, and adhering to a long-term strategy, manufacturers can develop outstanding industrial software products and achieve significant revenue. This financing round will bring more top talents to EMAN, and we will continue to increase efforts in research and development, service, and market promotion, launching more robust and internationally competitive industrial software and smart manufacturing solutions to contribute to Made in China. We will offer high-value products for our clients and create abundant returns for our shareholders."

The investment team from Shenzhen Capital Group Co., Ltd. remarked:

"EMAN is the leading brand in mold MES. EMAN’s products support most discrete processes such as injection molding, stamping, casting, assembly, and machining, offering vast expansion opportunities across categories. All products address a trillion-yuan market that integrates software and hardware. We are highly optimistic about EMAN's growth potential. On the technical front, EMAN heavily emphasizes innovative iterations, possessing long-term accumulated engineering experience barriers. Industrial software is the hidden 'golden instrument' for supporting the development and innovation of modern national industrial systems. The positioning of Shenzhen Capital Group is to 'invest in what the nation needs,' and we aspire to jointly contribute to the rise of domestic industrial software alongside EMAN."

A Partner from Rongyu Capital added:

"With the release of the 'Digital China Plan' before the Two Sessions, targeting 'digital China infrastructure' and 'core capabilities of digital China,' it's evident that industrial software—a representative of digital industrialization—will encounter long-term benefits. Companies like EMAN, exemplifying autonomous innovative capabilities, will encounter broader development prospects. Rongyu Capital is committed to steadfastly supporting real economic and industrial innovation in the digital economy, fulfilling due diligence obligations, and promoting both industry and investment enterprise development."

About the Investing Institutions

Regarding investment institutions

Shenzhen Capital Group Co., Ltd. (SCGC)

Founded in 1999 with initial investments from the Shenzhen government and additional social capital, SCGC focuses on uncovering and nurturing great enterprises and aims to be a discoverer and cultivator of innovative value. With a registered capital of 10 billion yuan, SCGC manages total funds of approximately 431.4 billion yuan. The firm manages 175 private equity funds, 13 fund-of-funds, and 13 real estate funds, focusing on investing in SMEs, high-tech enterprises with independent innovations, and emerging industry firms, covering information technology, biotechnology and health, intelligent manufacturing, new energy, new materials, the internet, consumer goods, and modern services across all stages of a company's life cycle. Upholding the "three parts investment, seven parts service" philosophy, SCGC propels investee companies towards rapid and healthy development through resource integration, capital operations, supervision oversight, and training guidance.

SCGC leads the industry in the number of companies invested and the number of listed companies. Due to outstanding performance in the venture capital sector, SCGC consistently ranks among the top in industry ratings by authoritative bodies such as the China Venture Capital Association, Zero2IPO Group, and ChinaVenture. From 2016 to 2022, SCGC was recognized as the leading local venture capital institution in Zero2IPO’s annual China Venture Capital Institution ranking.

Rongyu Capital

Based in Shenzhen, Rongyu Capital Management Co., Ltd. (Rongyu Capital) specializes in the medical and health industry while focusing on hard technology, the digital economy, and other innovative fields. The investment team, led by some of China’s earliest investors concentrating on the medical and health industry, boasts nearly 30 years of financial experience and 20 years in private equity investment. With the pioneering investment concept of "financial capital + industrial intellectual capital," Rongyu Capital focuses on the core area of precision medicine in healthcare and hard technology tracks oriented towards product technology innovation and domestic substitution. Several companies within its portfolio have gone public in domestic and international capital markets.