EMan Mold Intelligent Manufacturing Management System

Digitalized Full-process Management of Mold Manufacturing

In manufacturing plant logistics, warehousing and transportation are crucial processes involving the storage, turnover, production, and shipping of vast quantities of materials, ranging from raw items to semifinished and finished products. Poor management in these areas can lead to discrepancies between inventory records and physical stock, potentially disrupting production and delivery schedules, causing stockouts, and ultimately harming corporate credibility.

Traditionally, warehouse goods are stored directly on floors, leading to extensive space consumption with inefficient use, low storage precision, prolonged delivery times, and high product damage rates. In addition, manual warehouse operations using forklifts impose significant labor demands, limit efficiency improvements, and increase the likelihood of errors.

Thus,manufacturing companies must possess advanced production management and supply coordination capabilities, implementing automation and intelligence in warehousing and logistics. This enables real-time, quick, and accurate visibility into warehouse conditions and operations, ensuring smooth and on-time production, shipping, and receiving tasks.

Sprint Precision Technologies,a manufacturer specializing in precision components for semiconductor equipment, has partnered with EMAN to build an intelligent warehousing and logistics system centered around automated storage and retrieval systems (AS/RS) and Automated Guided Vehicles (AGV). This collaboration has resulted in precise material management, reduced labor and warehouse space requirements, and significantly improved warehouse operational efficiency, laying a solid foundation for advancing intelligent manufacturing.

Breaking Monopolies

Seeking Global Market Influence

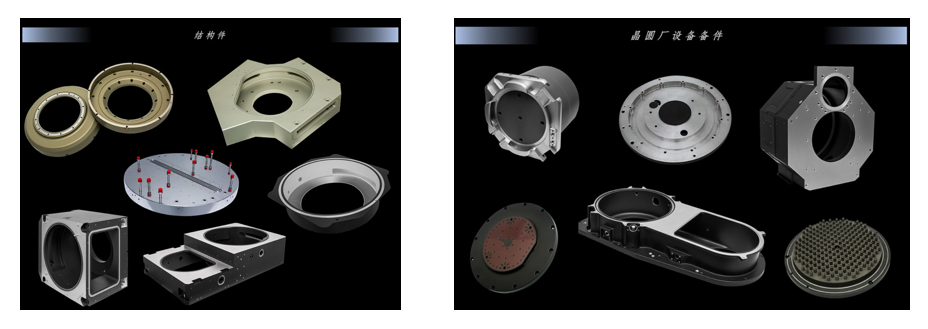

Sprint Precision Technologies (JiangSu) Co.,Ltd. (hereafter referred to as Sprint Precision Technologies) is a high-tech national enterprise engaged in research, development, manufacturing, sales, and service of semiconductor devices, integrated circuit equipment and components, and precision parts for aviation and advanced equipment. As a key supplier to leading domestic integrated circuit equipment firms such as AMEC, NAURA, and SMIC, it ranks among the top ten in its domestic industry. Sprint's latest "5nm chip process etching machine core components" hold strategic significance in driving the localization of core semiconductor equipment components in China.

Sprint Semiconductor Products

Planning and Implementing Intelligent Warehousing and Logistic Solutions

Sprint Precision Technologies remains focused on the indigenization of key components for large-scale integrated circuits, continually increasing R&D investments, executing smart workshop upgrades, and enhancing production processes. Previously, semiconductor parts, like photolithography machine semifinished parts, were stored on pallets in workshops, requiring significant time and effort for manual retrieval and often resulting in errors. Recognizing the necessity of automating and intelligentizing logistics within high-end manufacturing, Sprint Precision Technologies acknowledged these warehouse and logistics challenges.

EMAN provided Sprint Precision Technologies with a comprehensive digital smart factory production solution, including manufacturing operations management, intelligent warehousing, and intelligent logistics systems. Following approximately three months of implementation and optimization, the first phase of the intelligent warehousing project featuring an AS/RS was successfully launched and operational.

Sprint Precision Technologies initially leveraged EMAN's intelligent warehousing system, utilizing AS/RS, intelligent conveyors, a Warehouse Management System (WMS), and a Warehouse Control System (WCS) to standardize management and automate warehousing logistics operations, significantly increasing labor efficiency and operational performance.

The newly constructed intelligent high-rise warehouse stands over 10 meters tall and has nearly 2,000 storage slots.

A new automated warehousing facility for photolithography machine semifinished goods has been built, standing over 10 meters tall and equipped with a twin shuttle stacker crane, a single-reach stacker, and several conveying and detection devices, as well as beam-type racks with over 2,000 pallet positions. Each position can support a unit load of up to 500 kg, with a total storage capacity of approximately 1,450 cubic meters. The intelligently structured warehouse has greatly expanded storage capacity, saving roughly 2,500 square meters of ground space. Unlike former ground stacking methods, these high-rise racks enable orderly, efficient storage and retrieval, and strict segregation based on item size.

Launching the EMAN Intelligent Warehousing and Logistics Management System

The EMAN WMS connects upstream with ERP systems, sending material, stock-in, and stock-out instructions. After the WMS executes logistical tasks, the WCS coordinates equipment to manage incoming and outgoing stock operations, with AGVs autonomously delivering items to designated stations.

The EMAN intelligent warehousing logistics system encompasses essential functions such as personnel management, department oversight, unit measures, material records, pallet accounting, equipment records, channels, entries, racks, and inventory, along with inventory checks, task management, and statistical analysis. This advanced solution improves warehouse management efficiency, enabling accurate data analytics and automated equipment monitoring and scheduling. Additionally, EMAN developed custom handheld PDA functionalities for Sprint Precision Technologies, enabling swift mixed-palletization and multi-task outbound operations.

Before this project's implementation, comprehensive tracking of warehouse materials was challenging, with manual data analysis proving burdensome. The intelligent warehousing system records all stock transactions, with a visual dashboard providing real-time inventory and stock status insights, eliminating the need for additional staff for complex data computations. Automated cargo operations have reduced manual work intensity and dependency while improving accuracy.

Ongoing Implementation of the AGV Intelligent Logistics Project

With a short implementation period and smooth trial operations, the automated warehouse project was quickly launched, garnering positive feedback from Sprint Precision Technologies and setting a firm foundation for continued collaboration. Following the warehouse's successful operation, Sprint Precision Technologies immediately pursued AGVs to minimize manual handling and increase logistic efficiency. This AGV logistics project, also executed by EMAN, aims at automating intra-warehouse and inter-facility transportation and sorting, seamlessly integrating production and logistics, and facilitating lean production for a fully intelligent factory. The AGV project is anticipated to go live in June.

Through this intelligent warehousing initiative, Sprint Precision Technologies has achieved significant enhancements in material turnover efficiency and spatial utilization, fully automating and initializing the warehousing logistics link while providing robust support for production processes. This boost in innovation also strengthens product market competitiveness, creating new growth channels for the company. EMAN remains committed to delving deeply into all aspects of intelligent manufacturing, incorporating digital technologies into production and operational scenarios to empower manufacturing enterprises effectively in their smart manufacturing transformation.